Organization: W. M. Keck Center for 3D Innovation, The University of Texas at El Paso, El Paso, TX

Date: February 2010 – December 2020

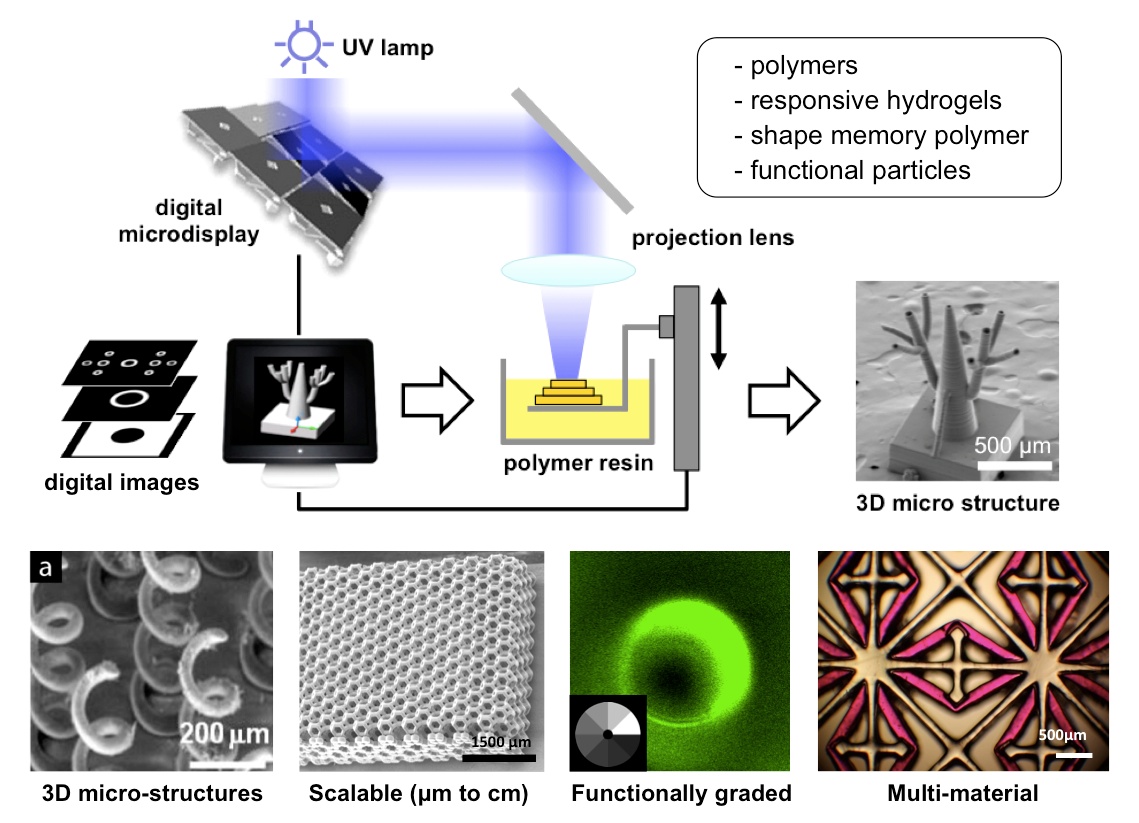

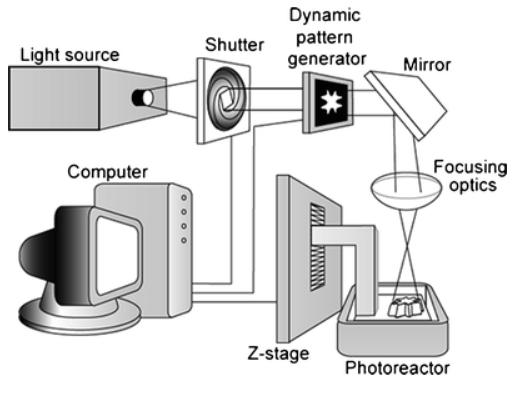

Background: A non-commercial microstereolithography (μSL) system – an additive manufacturing technology – was selected as part of a research and development grant to develop fabrication techniques to produce micromatrix structures for drug delivery applications. Process variables (e.g. UV light exposure time, layer thickness, resin makeup) needed to be optimized to produce the 3D microstructures of correct dimensional accuracy. Various tests were carried out to dial-in process parameters to achieve an acceptable dimensional variance.

Objective: To achieve a base material for optimal fabrication of 3D microstructures using microstereolithography technology.

My Position: Undergraduate Researcher

My Role: I was solely responsible for maintaining, operating, and conducting research using the non-commercial μSL system.

Technical Fundamentals: Material Science, Mechanics of Materials

Skills: Material testing, manufacturing processes, data analysis, computer-aided design (CAD)

Technology Tools: Non-commerical μSL system, stereo microscope, SolidWorks, MS Excel

Results / Outcome: Achieved a base material for optimal fabrication based on dimensional accuracy of 3D microstructures. Improved the non-commercial μSL system’s future usability by completing a detailed user guide and manual with operations of all working components and troubleshooting.